Certain applications require non-magnetic screw drives. These applications are found primarily in the field of medical technology, for example in MRIs or other devices where metallic components are a hindrance to the process. Even in an already magnetic environment, a screw drive must be equipped as anti-magnetic as possible.

The choice of the threaded nut is the smaller problem in the implementation. Numerous standard and sliding plastics are available to the user. The use of special bronze alloys can also be a solution.

When choosing the spindle material, it becomes a little more difficult. Stainless steel is generally much less magnetic than free-cutting steel, but this is often not enough for use in certain applications. In principle, the respective alloy must be checked precisely with regard to its mechanical properties. From this it can then be deduced whether a material can be machined or cold-formed (rolled).

Titanium can often be used, and the threads can also be easily formed by rolling, but the machinability of this material is not very good. The manufacture of the spindle journals can therefore result in greater costs.

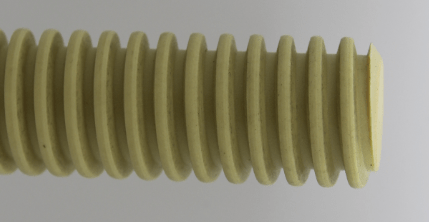

Plastic spindles are easy to cut, whirl or inject. The low strength of plastics is often a problem, as is the lack of dimensional stability due to thermal and hygroscopic influences (heat and moisture swelling).

Excellent alloys in terms of antimagnetism and suitability for rolling and machining can be found in the non-ferrous sector. Ms58 is often used for X-ray machines and MR tables.

Depending on the alloy and application, aluminum can also be a solution with regard to the non-magnetic design of a screw drive.

junaspin will be happy to support you in the selection and design of your screw drive. We would be happy to discuss with you how we can achieve sufficient antimagnetism in your application. In addition to the technical requirements, economic aspects are of course also relevant here. We can incorporate relevant experience from “real applications” here.