We have already developed many special solutions and manufactured custom-made products for our customers.

Situation:

In an application for adjusting a bed in a caravan, the previously used TR16x4 screw drive caused noise problems due to self-excited resonances. These noises are amplified by the aluminum construction of the recreational vehicle.

Task:

A noise-free, maintenance-free screw drive was to be developed.

The solution:

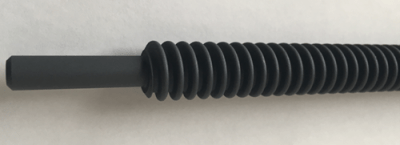

junaspin developed solution concepts with the customer and supported the customer’s attempt with numerous sample productions. To get the noises under control, a trapezoidal thread with rounded thread flanks was developed. This spindle was also made with increased straightness. For a test, the spindles were also provided with various sliding coatings.

Situation:

In one application in the packaging industry, there was high wear on the trapezoidal flange thread nut made of Rg7.

Task:

The costs associated with frequent replacement should be reduced.

The solution:

In consultation with the customer, a two-part flange thread nut was designed. A housing made of V2A was designed with a sliding insert made of Rg7. As a result, only the sliding insert has to be replaced as a wear part during repairs and maintenance. A side effect was that sliding inserts made of different materials could also be tested at low cost, for example from inexpensive POM or the higher quality GBZ12.

Situation:

In a plastic injection molding machine, the high-helix lead screw that was used to demould threads on injection molded parts failed due to years of use.

Task:

A replacement had to be found promptly so that production did not stand still for too long. The relevant standard parts suppliers do not have the required dimensions in their range.

The solution:

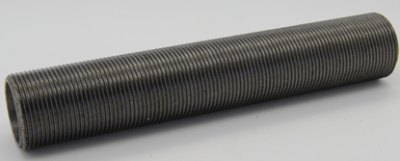

Since it was a one-off production, the only solution was to cut the thread. Within a few days, the spindle with a diameter of 20mm and a pitch of 70mm could be manufactured according to a sample.

Situation:

In a large project with almost 1000 Rg7 threaded nuts, flange threaded nuts with a flange diameter of 100mm were used. The thinner, cylindrical part of the threaded nut only had a diameter of 62mm over a length of 90mm.

Due to the cost pressure, a solution has to be found to manufacture the parts more cheaply.

Task:

Due to the cost pressure, a solution had to be found to manufacture the parts more cheaply. When manufacturing from a semi-finished product made of solid material, around 45% of the weight ended up in the chip bucket.

The solution:

Together with a partner, junaspin developed a nut blank for cast blanks that provided an enormous price advantage when purchasing materials.

Situation:

In one application in the graphics industry, there were problems with the use of the standard trapezoidal thread spindles due to the buckling.

Task:

In addition to changing the material to 30CrNimoV, a thread profile with a larger core diameter should also be developed while maintaining the pitch. The surface contact area of the thread should nevertheless come close to that of a standard trapezoidal thread.

The solution:

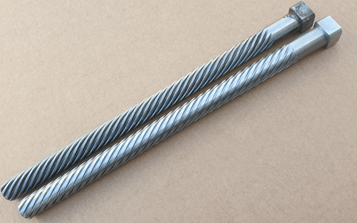

junaspin supplied a spindle made of high-strength steel with a flat thread profile and a high pitch.

Situation:

For a large project in the field of scaffolding, M27 metric threads should be rolled onto a pipe. In the application, the threaded rod always had to be designed as a tube, since the rods have to be telescoped. However, a drawn tube was not yet available for prototyping.

Task:

The pipes required for series production were to be delivered from Asia and had corresponding delivery times. Nevertheless, a solution should be found with which the entire assembly could be tested.

The solution:

junaspin delivered the first 15 pipes that were needed for the prototype in a deep-hole drilled version. The length of 500mm could be manufactured with one clamping.

Situation:

In an existing application in a chocolate factory, the lifter had to be retrofitted with a safety nut.

Task:

The original manufacturer of the ball screw drive could no longer be found due to the insolvency of a supplier. The procurement costs of a new ball screw drive would have been in the high 5-digit range.

The solution:

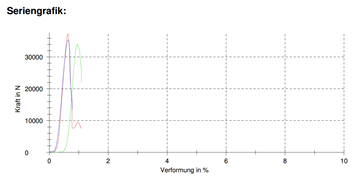

junaspin was able to receive a section of a similar spindle from another system that was shut down from the customer. The pattern could be measured and the thread profile could be “reproduced” accordingly. The parts were made from a 42CrMo4 and then tested for the required strength in a test laboratory.

Situation:

Due to the cost situation, a machine manufacturer had to replace the previously used ball screw drives with trapezoidal screw drives.

Task:

A low-backlash version with very high repeatability also had to be implemented with a sliding screw drive.

The solution:

The rolled spindles were individually measured and sorted. The flange nuts were then individually adapted to the respective thread with little play. Increased demands were also met with regard to the perpendicularity of the flange, the straightness and the fits and the concentricity of the spindle. In spite of the complex production method, the costs could be reduced enormously.

Situation:

A threaded spindle from the fittings industry should be made of a very high quality and expensive stainless steel. The spindle plate had a diameter of 85mm, but the thread was a TR40x7 left-hand.

Task:

A production method that is as cost-effective as possible should be found for rather small quantities.

The solution:

After the costs for a variant made from the solid material were too high and the delivery times for hot-formed blanks were enormous, junaspin developed a 2-part solution together with the customer. The concept for connecting the two individual parts immediately won over the customer.