Thread nuts are mostly manufactured mechanically due to the required quantities and accuracies. When using plastics, however, the manufacture of injection molding processes is also an option.

Threaded nuts can be completely injected. A thread with small pitches is removed from the mold with a driven tool core (for example with single-start trapezoidal threads, round threads, metric threads, etc.) or with very high pitches also with a slide (e.g. with multi-start trapezoidal threads or high-helix threads without self-locking).

Alternatively, partial production using the injection molding process is also worthwhile. For example, the “nut body” can be injected and the thread is produced mechanically, or “nut blanks” can be produced and the component only partially machined.

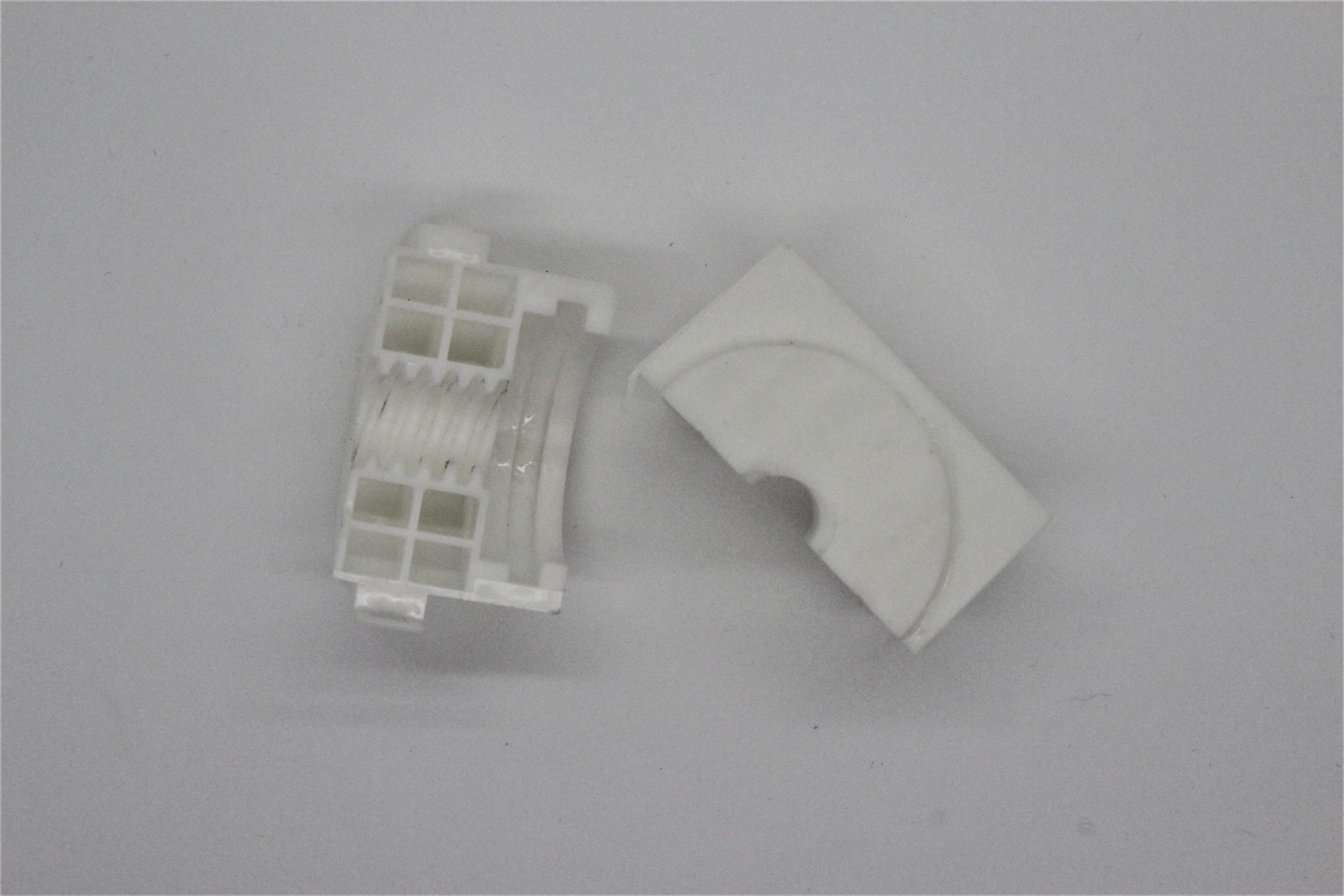

Often, threaded nuts are also manufactured in two parts using the injection molding process. Individual “nut halves” are not only very easy to demold, they also make assembly much easier

Through the use of rapid tooling concepts, i.e. the production of tools made of aluminum, small series from around 100 pieces can also be economical in the injection molding process.

Injection molded nuts should not be constructed with thick walls. In addition to sink marks, there is a risk that air inclusions (blowholes) could weaken the component. This problem can be countered with franking. The required strengths can then be achieved by bracing.

In the development of injection-molded nuts, it has proven useful to use materials that are available both as semi-finished products and as granules. A series application can be checked with machined parts.

junaspin will be happy to support you in the selection of materials and the design of your threaded nut. We have extensive knowledge of toolmaking and materials science. In addition to the technical requirements, economic aspects are of course also relevant here. Thousands of test results are documented in our database. In addition to the pure calculation, experience from “real applications” and tests can also be incorporated.