Since radial loads of a screw drive are usually absorbed by linear guides, only the dead weight of the unsupported spindle applies with regard to the deflection of a spindle.

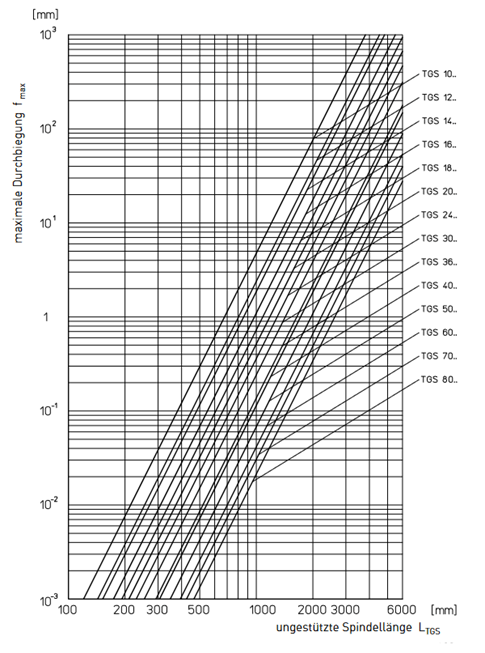

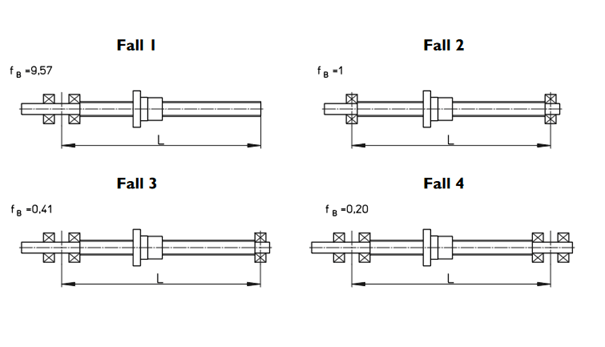

In addition to the weight / meter of the spindle and the strength values of the material, the unsupported length is particularly relevant for calculating the deflection. There is also a correction factor that takes the spindle bearing into account (graphic case I-IV).

The deflection of the spindle that occurs during horizontal installation can increase in the application Noises and lead to increased wear.

This can be remedied by shortening the unsupported length, increasing the diameter or changing the mounting.

junaspin is happy to support you in the selection and design of your screw drive. We are happy to calculate the deflection in your application for you. In addition to the calculation, we can also incorporate experience from “real applications” and tests.