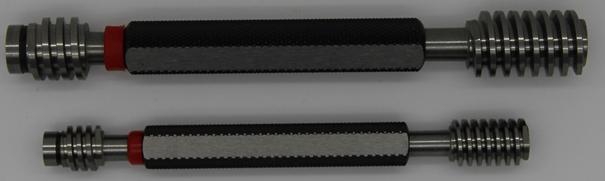

The mobility of threads is usually determined by means of Ring gauges or plug gauges checked. By arrangement, a nut or a spindle can also be used as a counterpart for teaching. Gauges can be made for threads that do not conform to DIN or that require increased or reduced play.

In the case of plastic nuts, gauge accuracy can only be checked directly after production. Hygroscopic and thermal influences can subsequently lead to dimensional changes in the manufactured components.

The basis for testing the threads produced are the respective DIN standards, for example DIN103 for trapezoidal threads or DIN405 for round threads.

In addition to the threads, all other tolerances as well as shape and position tolerances are of course checked. Material tests can also be carried out.

The materials used are also checked

junaspin supplies screw drives with corresponding works certificates, works certificates and acceptance test certificates on request. According to EN10204, certificates 2.1, 2.2, 3.1 and 3.2 are required in particular. The initial sample presentation can take place with EMPB as well as with PPAP according to VDA. A 100% check is also conceivable.